While doing the massive Dana 44 Teardown, I always knew I’d have to swap out the pinion gear to match my rear axle ratio (3.55). These old 1988 Econolines had a lot of different gear ratios, but one of the more fuel-economical options was a 3.55 rear axle. If you have a 4.55 or 4.10, you could haul or tow more, but if you are looking for high mpg and low RPM options, buy a van with a 3.55 ratio.

If you want to determine your van’s gear ratio, just check the axle information on your sticker in your driver’s door jamb. There is an axle code on the sticker, and you can cross reference it with the Axle chart from FTE.

Since I’m retrofitting a Dana 44 front axle on a non-4×4 Econoline Diesel F250 Clubwagon, there isn’t a chart for me to figure out my current pinion gear ratio in the donor Quadravan axle.

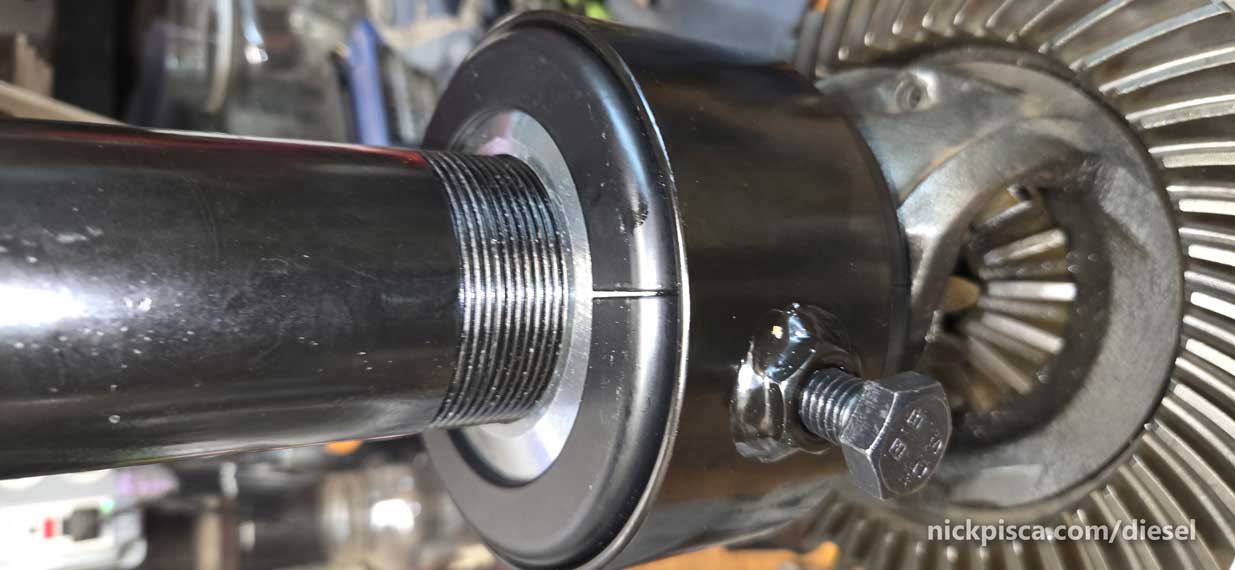

If you read my Teardown article, you learned that I did the crude ratio test when I had the differential housing sealed up. Just turn the yoke and count the rotations of the axle shaft by the rotor. I did that, and I got an approximate count of 4-4.25 turns per rotation, which averages about 4.10. That’s fun and all, but if you want to know the actual axle ratio, you read the numbers on the pinion ring gear. See below: 45 11 1

45 divided by 11 equals 4.10.

http://www.southerncaltruckparts.com/

This won’t work on the van. I needed to source a 3.55 pinion ring gear and pinion.

I tried the usual Chinesium Rock Auto garbage, and the expensive Summit online resources, but things were not suitable. Then I found Southern California Truck, Van & 4×4 Parts. Marty worked with me to get everything I needed, and I highly recommend his shop.

Originally, he got me a 3.55 pinion ring and gear, but after I got it home, I researched that Dana 44’s are unique. They have a different carrier for the 3.92 and up. Since my current ratio is a 4.10, I can’t use the 4.10-carrier with my 3.55 ring gear. If you want to see the difference, the mating surface is sunk lower on the smaller ratio ring gear.

Differentials Website shows this really well with this diagram: https://differentials.com/technical-help-2/carrier-breaks/

I called Marty up and asked him if he had the carrier in stock as well, and of course, he does. He even said to bring in the current 3.55 ring and gear, and we’ll just swap it for a 3.55 dana on the carrier. We added a small amount for the cost of the carrier, and this even included the spider gears.

All I had to do was clean off the dust and install new bearings. I think these parts were on the shelf for decades. That’s ok, because I’d rather have stock parts, instead of Chinesium. On my way out of the shop, Marty gave me his cheat sheet on how to read differential “patterns.” This was immense help. I didn’t realize just how much I was going to use this.

I drove back to the shop to remove the differential carrier and get started with the new install. Prior to removing the bearing caps, I marked them with “R” and “L” so that I knew which cap was on which side, and which orientation as well.

Using a 1/8″ thick piece of aluminum, I used that to extract the differential from the housing. Wedge it in the carrier opening near the spider gears, and turn the yoke. It’ll rotate and pry out the differential. Aluminum is a good tool, because it can’t scratch or ding your steel.

Empty diff housing.

While everything was apart, I popped out the axle shaft seals, but I’ll post a small article about that on a different day. I just want to focus on Diff swap here.

First, let’s very that the axle shaft spline count is the same. My 4.10 is a 30-count.

Let’s check this dusty 3.55 carrier and see what we got.

This worked way better than Harbor Freight.

That’s good. Another way to check is to slide the axle shaft into the carrier and see if it fits.

I need to get these trashed bearings off the 3.55 carrier. I bought new ones since these dusty bearings are totally shot.

I tried to use a crappy basic Harbor Freight bearing puller, and I basically broke it. Then I ordered another puller from Amazon, and it broke as well. These bearings were VERY fused to the carrier race. Ultimately, I broke down and bought a Cadillac type bearing extractor that is supposed to work on the most stubborn bearings. Bestool Carrier & Pinion Bearing Puller.

It’s a clamshell style puller that uses concentric extraction to minimize damage to the bearing.

Then use a impact driver (or socket wrench, if you are a masochist) to ratchet the top threaded rod to extract the bearing.

The clamshell just barely fits around the bearing shims on the carrier.

Well, after 5 minutes of hammering destroying my ears, I came to my senses and put in some ear plugs. It’s going to take a long time of ratcheting to get these old bearings off. Wear ear protection.

It’s almost off.

Success! That was loud. The bearing is in the clamshell. (NOTE, install the bearing race on top of the bearing when using the clamshell extractor. It’ll protect the bearing.)

I saved all my shims in the order they were installed, just in case I needed to use them again. I know that they won’t work in the new diff housing, but I keep everything documented regardless. I’ll use the same spacer distance as a starting point for the pinion ring pattern.

Flip over the carrier, and do the same with the other side bearing extraction.

Time to pull the old bearing off the pinion as well. I don’t have as many photos, but it’s basically the same thing. There are no bearing shims on the pinion because the shims go behind the inner bearing race, which I’ll go over later in this thread.

More information to come, just need a break from writing.