I’m trying to find time to work on this van inbetween work, work, and work, but I’m getting there. The latest achievement was trying to grind off the rivets on the crossmember, so these i-beam brackets are gone.

Check out Part 1 of the demo project here:

Last I left off, I was going to rip these riveted brackets off.

The rear rivets were already kind of loose. You can see the gap in the image above. I wonder if that was a contribution to the slop in my steering.

Well, I have a dozen cutting discs for my grinder, but no metal grinding discs. Not ideal, because I can’t get the cutting discs into the cavities from the side. I had to come in from the top of the rivet with a 1/16th thick disc, and work my way over and over and over until it was ate up. Slow going.

Finally the rear mount came undone.

Looks so empty.

Moving to the front bracket.

The front bracket DID NOT want to move. I ground down the rivets, and got them down to no head at all, but just the metal pressure fit to the hole was enough to resist a 2ft long pry bar. I ended up drilling the rivet necks out with a metal bit and cutting fluid.

I left the rivets in, because rather than trying to pound them out, I might as well just cut them out with the upcoming modifications to the crossmember.

So, I have to figure out how I want to cut this crossmember. I rolled the axle to the front of the van to get an idea of the pumpkin location.

How does this line up with the center axis of the pinion?

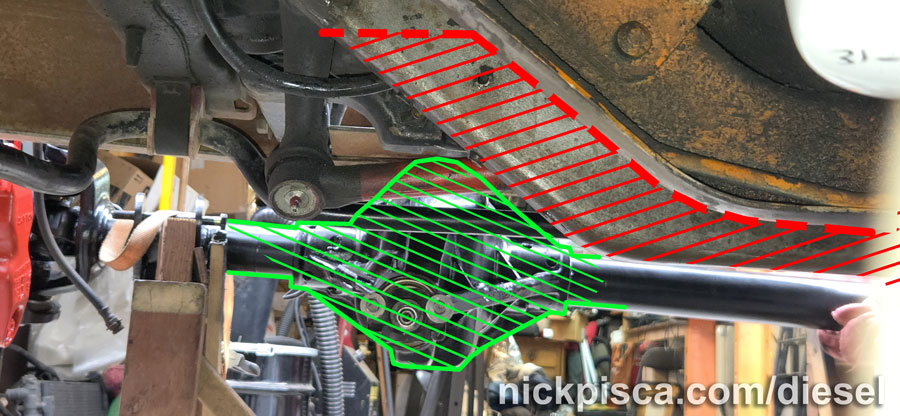

Primarily, the pinion and gear housing matches up with the diagonal of the crossmember, especially the lower flanges. Looking from under the van forward, you can see the issue.

In red, this is the material that will need to be cut off the crossmember. In green, this is the axle housing.

I ran out of time to cut up the crossmember, and it started raining. I went into the house to do some final research before making some major modifications to my frame and crossmember.

While looking at the Pathfinder manual, the crossmember looks different than mine. Check this out:

The top of the crossmember has a slightly different shape. There is a knob on the driver’s side under the oil pan. That’s disconcerting, so I need to do more research.

Looking at Boomer’s crossmember, there is definitely a different motor mount than mine.

Copyright Boomer – User: spencyg https://forum.expeditionportal.com/members/spencyg.1533/

I know my diesel engine isn’t the most common, but it should be very similar to the 460 engine that Ford had back then. The mounts should be more or less the same, with them riveted to the top and rear flange of the crossmember. No knob on Boomer, as far as I can see.

While skimming through all the photos in the Pathfinder Vans Owners Club, I’m starting to see a pattern. All this older Ford Pathfinders have a different crossmember than my van. Check out this guy’s van with the “knob.”

https://www.facebook.com/photo/?fbid=10226027514296396&set=g.965424677164927

Alright, so maybe Ford had a boxier crossmember for van’s older than my 1988? I went through my archives when I had my 1984 E350, and here’s the van’s crossmember:

Definitely NO KNOB on my 1984 van.

Now, I’m starting to second guess myself. Maybe the pathfinder kit was different and came with a custom crossmember? I kept digging. Sure enough, other Ford vans had the same box-and-knob style crossmember. Here’s another van with the same feature.

https://www.facebook.com/photo/?fbid=1061494185159463&set=g.965424677164927

The knob would help with transmitting the load. The 7.3 IDI Engine is 1100 lbs, so miscalculating the cuts in my crossmember could be devastating to the stability of the frame.

Need to figure out my plan before getting too crazy.

I’m going to jack up the van 4 more inches in elevation so I can roll the Dana 44 directly under the crossmember. Let’s line this up and see what kind of meat has to be trimmed off this beast.