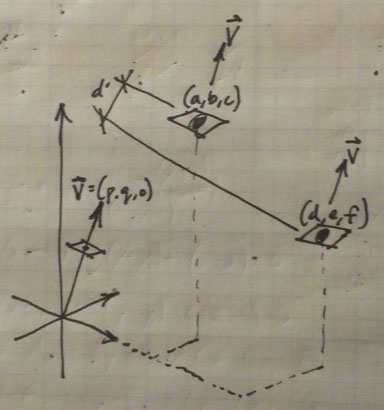

Another episode in Functional SLS 3D Printing: Making an adapter for a PVC downspout into a standard rain barrel. Check out the video:

This project was interesting for a couple reasons. First off, I implemented a wifi power supply to the Sintratec Kit, to allow me to e-shutoff the device remotely. I’ve been in situations where I was away from the machine, but monitoring it via my smartphone-linked webcam, but couldn’t kill the machine if there was an error. So far, I haven’t encountered this scenario, but now I have the peace of mind to know I can abort the mission from anywhere with a wifi or cell connection.

Next, this print job combined a couple projects in one. It ran on about 100 models in one bed, along with the adapter. I even packed in extra models inside the tube, because if there is space, I might as well use it. I used 75% old powder and ran it at a hotter temp than usual. It was on the cusp of powder fusion, so I wouldn’t try this again unless I was trying to really get close to the corners of the bed. Also, it was 1067 layers, and it successful ran to completion. I did a 10-layer “forced sinter” on the startup, after an extra long warm-up time (about 120-150 minutes) to ensure all the powder was ready. I watched until the end, where it applied only 4 layers above the last print layer. That’s a buffer of only 0.4 mm. WILD.

If you want to download the STL File of my barrel adapter, click here: Large_Barrel_Hole_Adapter_(Fine_Threads) You may want to slightly offset the threads by a hundredth of an inch just to make your adapter a little less snug. But if you like it like that, then leave it as is. 🙂

I’ll keep making videos of Functional SLS Prints while this lockdown continues. It’s a good opportunity to test these things out. Onward!

![Functional 3D Printing | Rain Barrel PVC Adapter [VIDEO]](https://www.nickpisca.com/sherpa/wp-content/uploads/2020/05/20200522_bungholesfw.jpg)

Recent Comments