1998 VW Jetta

TDI VO Conversion Installation Thread ††††††† Return to Main Page

Dual

Tank System †††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††† < 1† 2† 3† 4† 5 >

WVO & SVO Compatible

Design and

Installation:† Nick Pisca, July 2007

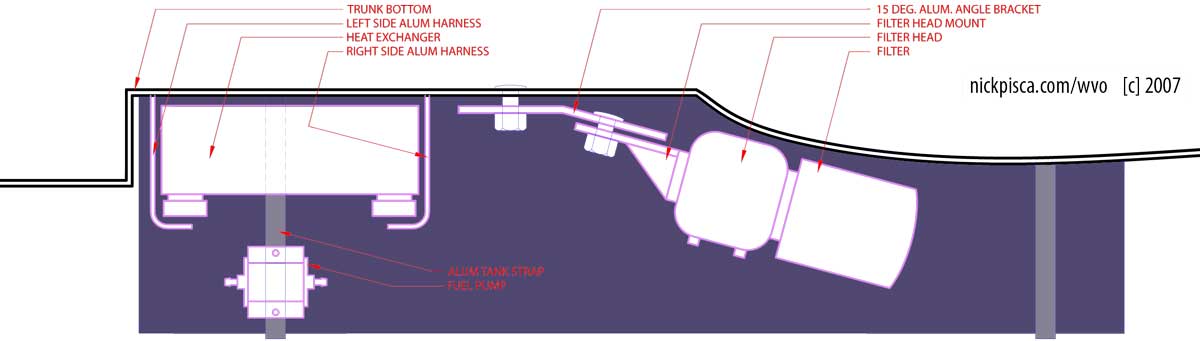

Rear Components and Bundle Installation:

The

following images show how the components and bundle were installed.†

EMPTY SPACE UNDER THE

CAR:

When I

first planned out the rear system, I speculated that the components (a heat

exchanger, fuel pump, and filter head) would all fit besides the tank directly

behind the rear tire.† Once the tank was

completely installed, it was apparent that this would be impossible.† The HotFox fittings

would obstruct all side-layout scenarios, so I moved to the space between both

tanks under the car.† This space was

eight inches deep at its highest point, which forced the filter head to be

horizontally or angle mounted.† The filter

head was 9 inches tall.†

The

filter head required a custom metal angle to set it at fifteen degrees.† I wanted it to be as steep as possible to

reduce spilling oil when a filter required changing, but fifteen was the most I

could get.†

Next, I

placed the 20-plate heat exchanger up against the tank and underside of the

trunk floor.† To secure it, I fabricated

two bent aluminum strips on each side.†

If I needed to pull it out for some reason, I could just push back this

harness.† They hook and connect to the

top of the exchanger, which is upside-down.†

I

thought the fuel pump could still be mounted on the side, but that proved

difficult again because of potential hose kinking.† A spot directly the heat exchanger worked

best.† Glenn predicts my cheapie fuel

pump will give out soon anyway, so mounting where itís easy to remove would be

good.† I didnít even bolt it in place;

the mounting was accomplished by using some aluminum wire loops.†

HOSE ROUTING:

Since

most of my fittings are all pointed downwards, I needed to be creative to avoid

kinks.† AutoZone sells Goodyear brand

heater hose coils that are meant to hold a specific bend in a specific

location.† They slide onto the hose and

have a metal backing that retains the desired shape.† This is important for my design, for I canít

have any hoses dip below the tank; if it did, not only would I lose all my

heat, but also it could get caught on something when I drive.†

I found

that these coils have a secondary effect that reduces kinking for moderate

turns.† Since the store-bought coils

still have a little play with the hose, it can still kink or stretch, so I used

some of my aluminum wire to produce my own.†

It doesnít have the backing, but it still works really well if itís

snug.

I would

have used more 90 degree bend fittings, but in most cases, it wasnít

possible.† The heat exchanger had some

crazy custom hose fittings that I could replace.†

EXHAUST SYSTEM BYPASS MINI-BUNDLE:

For most

of the bundle, I used large extruded insulation with Hose-On-Hose (HOH)

heating.† This insulation had a wall

thickness of 3/4Ē and averaged a diameter of 3.Ē† There was a small distance from the back of the

car to the suspension system that couldnít accommodate this large bundle.† So before I installed the large insulated HOH

setup, I made a thin segment out of 3/8Ē copper and aluminum bendable pipes.† Just in case you donít already know, you

shouldnít use copper hoses or fittings for the VO system.† There has been a lot of research on this

topic and copper can react with vegetable oil.†

This

smaller bundle is probably a better conductor of heat transfer anyway, because

I connected the two copper and single aluminum tube

with silver solder.†

START OF THE BUNDLED TUBES

Since my

major HOH bundle starts by the muffler, I was able to make some steep bends in

the copper and aluminum tubes from the mini-bundle.† This lifted the tubes up against the floor

boards to clear the suspension system.†

As you can see, I wanted to have a lot of insulation to protect the

bundle.† These were 6-foot segments from

B & B Hardware and I used zip-ties to make an A-A-B pattern.†

The

make-up of the bundle comprises three 3/8Ē fuel hoses (coolant-in, coolant-out,

& fuel-supply) and a 5/32Ē vacuum tube for a VO return.†

POTENTIAL REWORK

The only

part of the system that makes me cringe is the mid-section of the bundle.† There wasnít a lot of room for a three-inch

diameter tube to go for this 3-foot distance.†

If you look at Jeffís configuration, he ran HIH and that afforded him a

low-profile system.† On mine, it does

hang down pretty far.† Iím tempted to

remove this section and make another mini-bundle to run closer to the floor boards.†

If I had

to start from scratch, Iíd contemplate doing the whole bundle with aluminum

3/8Ē bendable pipe.† Itís only 89 cents a

foot and if you can solder certain places together, youíll essentially have a

twenty-foot long heat exchanger.† Glenn said

it would be a pain in the ass to route the lines, but since itís not being

tracked inside the car, I donít think itís that difficult.†

COOLANT RETURN SPLITS AWAY:

I split

the coolant return away from the bundle right behind the passenger-side

tire.† This saves some space when I set

up the front heat exchanger.† From the

Image above:

R: VO Return

S: Coolant Supply

T: VO Supply

U: Coolant Return

Once

again, I used a section of the copper and aluminum bendable hose to manage the

transition through the fender.† If I just

bent the rubber hose into the fender, it could kink.† I re-bundled the three remaining tubes after

the interstitial metal segment.† Also,

this metal area is insulated with reflectix (not in

the picture.)

FENDER AREA:

This was

a good find for hiding the bundle.† If

you remove the plastic inner fender, there is a whole bunch of room for not just

the bundle, but if wanted to install a third heat exchanger, this would be the

place.† Iím even tempted to move my front

heat exchanger to this location, because the upper left side has a lot of extra

space.† I donít have an image of the

system with the inner fender removed, but this picture shows how the three

tubes work.†

COOLANT RETURN:

The

coolant return hose emerges up the firewall and connects in the heater core

hosing in a series configuration with a simple brass 3/8Ē-to-5/8Ē reducer.† The coolant supply hose (not pictured) runs

continuously around the engine and follows the VO lines from the selector

valves to the rear ďmini-bundle.Ē†

Later, I

came back through these areas and added some lower profile extruded pipe

insulation to this line.† Due the

conversion, the heater core is now the last element in the series circuit. †Saving as much heat as possible will decrease

my warm-up time.

Also,

the image displays the 14-gauge pink wire that is the load for the fuel pump in

the rear. †I ran it from the back to the

front, which may have been a mistake. †Later

I found that the Jettas have a few extra slots for

diesel supply and return. †Look in the

engine compartment near the diesel can filter; if you see a blue plastic line,

follow that to a metal tube that runs down through the floor boards. †If you can fish your electrical down this

path, you can have a really clean system.

END OF THE BUNDLE:

The

bundle completes it run in front of the air filter housing. †I found a reasonably-sized hole that

accommodates an uninsulated cluster of hoses. †I ran a 5/8Ē hose from the heater core for the

first part of the coolant supply line because I have a theory that the thermal

mass will retain more heat. †At the

bottom of the air filter housing, there is a heat exchanger that youíll see

later in the thread. †The heat exchanger

has a 3/4Ē coolant fitting so this works pretty seamlessly coming directly from

the heater core hosing (avoiding a reducer). †

This was

all post-insulated once the engine portion of the conversion was completed.

†

††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††††† < 1† 2† 3† 4† 5 >

[c] 2007 Nick Pisca . www.nickpisca.com/wvo . Waste Vegetable Oil Awareness and

Travel . www.nickpisca.com